FSP Power Mod 700W Power Supply

Dec 13th, 2008 | By Anthony

FSP Power Mod 700W Power Supply

Date

: 12/13/08 – 01:21:34 AM

Author

:

Category

: Power Supplies

Page 1 : Introduction

For a company who has been around as long as FSP, there is surprisingly, not very much news about them. Rather, FSP is the type of company who lurks behind the scenes. Being a major producer of OEM power supplies, we often tend to forget that FSP produces a line of their own!

Since 1993, FSP has been producing all sorts of power supplies for computers, industrial equipment and even for LCD panels. Today, they are now one of the largest manufacturers in the world with offices scattering the globe.

As FSP's first appearance at Overclockers Online, we are hoping for quite a show.

Page 2 : Features and Specifications

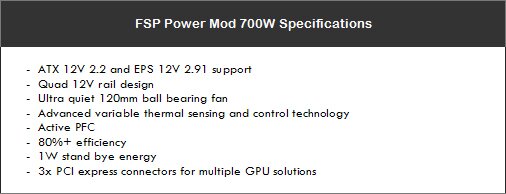

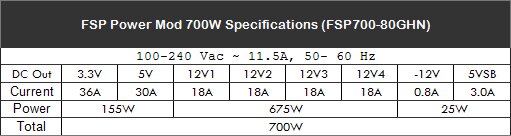

As of date of writing, FSP does not have this unit listed on their website; however we do have some information from the packaging.

Nothing too out of the ordinary here and the specifications are fairly typical for 700W range power supplies.

Page 3 : Package and Content

The Power Mod 700W comes in a fairly typical cardboard box, not too fancy, but with all the material one would expect.

All surfaces of the box are covered in product information and specifications.

On the back, we have a list of output information and some more features.

Inside, we have the power supply, Velcro wraps, a manual, an AC cord and the modular cables.

The power supply isn't much of an eye catcher, but decent enough looking. The unit is finished in a dark grey matte coat with a matching back fan grill.

The most predominant feature is probably the large 120mm fan which occupies the greater portion of the bottom of the power supply.

The 120mm fan situated on the bottom of the unit serves two purposes, first cooling the power supply itself, and second, acting as a system exhaust. Air is drawn from within into the power supply and then pushed through the perforated rear panel.

Towards the rear of the unit, we have AC plug, switch, and lots of perforation for airflow.

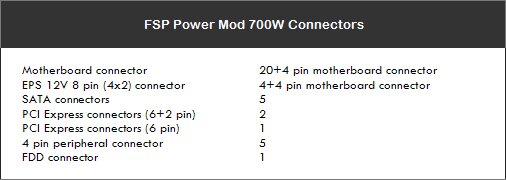

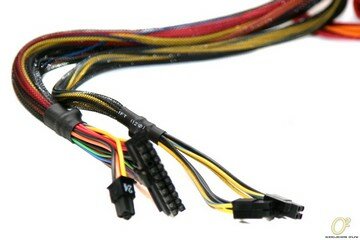

On the front we have the modular connector connectors. While this is a modular power supply, FSP has chosen to keep a number of connectors permanently attached to the power supply: the motherboard connectors and a single 6 pin PCI express connector – which definitely makes sense.

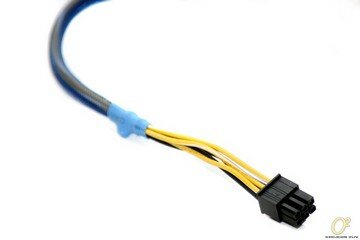

In the case that the user has chosen a higher end video card, two 8 pin PCI express connectors can be attached to the power supply through the modular plugs.

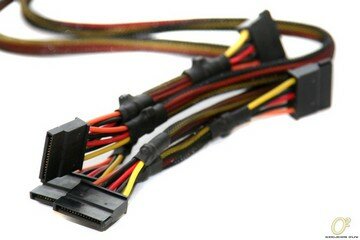

For hard drives, we have 5 SATA connectors.

And finally, five 4 pin peripheral connectors along with a single floppy drive connector.

Now with the exterior explored, let's peel back that warranty sticker and void the warranty!

I have to say, inside isn't the neatest assembly job I have seen. It may just be the excessive use of glue, but definitely, the assembly could be cleaned up.

Taking a peek at the capacitors, on the primary side we have a Teapo and on the secondary side, a mix of CapXon capacitors.

Page 4 : Testing Setup

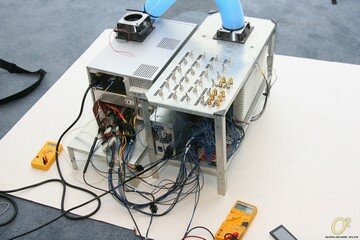

Quite unlike any other PC component, properly evaluating a power supply involves much, much more than running a battery of tests or sitting down in front of a shooter for a few hours armed with a pen and a pad of paper. Although, we have the utmost appreciation for a few headshots coupled with explosions, power supply reviews call for much more. The general mantra for testing power supplies tends to fall somewhere in the ranges of loading the power supply up to the top, and letting it suffer. We here at Overclockers Online are inclined to agree. Accordingly, our testing methods have evolved to allow for more sophisticated and accurate testing.

The dilemma here is: how to test a power supply without a computer system, but emulate a computer system? It is important to not forget that as much as we try to part from throwing a power supply into a computer system and watching how it performs, ultimately, what we are distancing ourselves from is precisely what we are trying to replicate. Simply, the ideal testing platform would be indistinguishable from a computer system, but graced with the accuracies of an adjustable load. However, since we do not have access to state of the art testing equipment, or the funds to purchase such equipment, we have built a custom load tester. While it does not offer adjustments in the thousandths of a decimal place, it does offer enough flexibility to test current day power supplies and beyond.

Using thick high quality 16AWG wires throughout and equally high quality connectors and switches, we have sought to minimize resistance in the lines while maintaining flexibility. All it takes is a flip of a switch to turn a desired resistor on or off.

A proper electronic load is a start, but we are going to be a bit more ambitious. A keystone piece of our testing mythology is the heat box. A system drawing 800W from a power supply produces quite a bit of heat, and to be testing such a power supply in an ambient environment is not only inconsistent with in-system applications but unrealistic and misleading. Our hotbox consists of nothing more than a case graciously donated to us from Silverstone. Recycling heat produced from the load tester using a series of controlled fans and a duct, we can control operational temperatures and push a power supply to its limits, or over.

Using the heat and load, we will run a battery of five tests: three cold and two hot tests. The three cold tests consist of 50% load, 80% load and finally full load. Naturally, we will escalate the strain on the unit by adding heat in the hot tests. The final two tests are 80% load and full load at approximately 50°C or more.

While the purpose and effects of 'burn in' are debated, doing so causes no harm. Prior to any testing, all units are run for a maximum period of one week without load. At best, this will stabilize the unit; at worst it takes a few hours off the unit's total life span.

In our tests, we will do our best to adhere to ATX specifications including cross loading and criteria for testing. The presentations of our results are designed for ease of interpretation and conciseness.

So, without any further delay, let us get started!

Page 5 : Testing

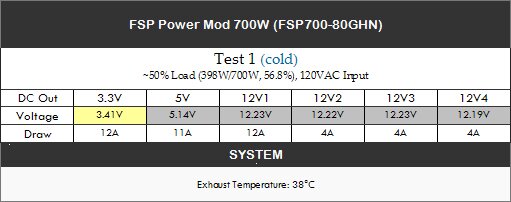

The aim of the cold test is to reflect ideal operational conditions where heat from the computer system is independent from the power supply. Still though, the term cold test would be misleading as things do get quite hot!

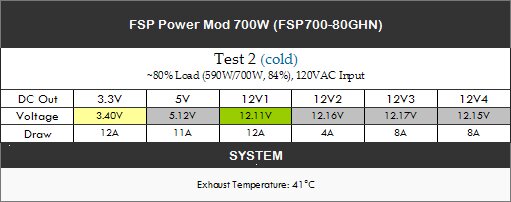

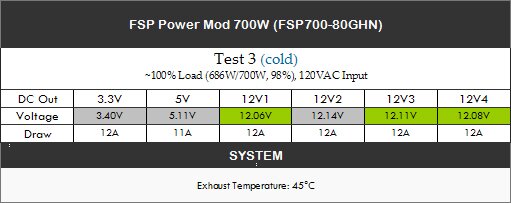

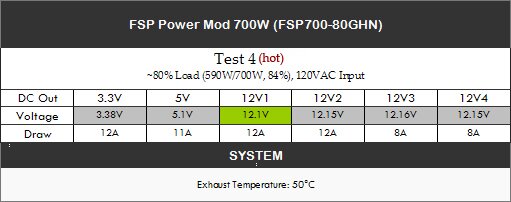

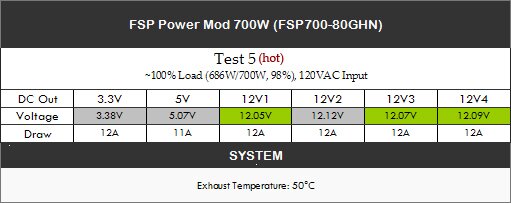

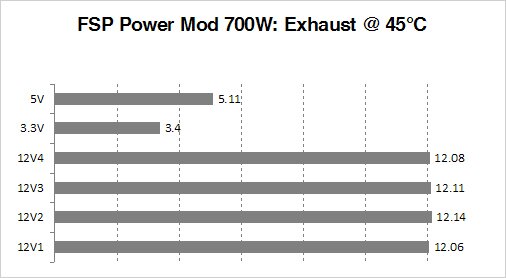

Not too bad for voltage regulation! The 3.3V rail was a bit high, but still fell within the 'less than 3%' mark.

In tests 3 and 5, with the heat turned up things got a bit more jumpy, but still good voltage regulation. While all rails slipped a few more points everything was still looking pretty good!

Having a look at Test 3 and Test 5, 100% load at optimal temperatures and at 50 degrees Celsius, we can see how heat affects performance.

To call first the first graph the cold test would be a bit misleading. Things did get pretty hot in there with a measured exhaust temperature of 45 degrees Celsius!

In terms of size, the Power Mod 700W is fairly typically sized and should have no trouble fitting into most cases, including our small form factor Silverstone case / hotbox. However, upon installation it was apparent that the cables were rather short. In a full tower case, this will be an issue.

Page 6 : Conclusion

For FSP's first review here at Overclockers Online, they haven't done a bad job at all. The Power Mod 700W may not be the prettiest unit out there, but it does get the job done. The unit remained quiet through all tests and the modular connections were a big plus.

Where the Power Mod 700W falls short is price. At the lower ends of $100 dollars, there are quite a number of options out there; including a number of units we have looked at in the past. That isn't to say the Power Mod is a bad unit.

The unit did perform well in all of our tests. As we slowly piled on the load and turned on the heat, the Power Mod 700W looked promising. The voltage regulation was steady and the unit remained quiet.

Advantages

- Performs fairly well

- Quiet

- Fully sleeved

- Modular

Disadvantages

- Expensive for what you get

- Short cables

Overclockers Online would like to thank FSP for providing a review sample of the Power Mod 700W for review and Silverstone Technologies for providing the chassis for use in our load tester.

The FSP Power Mod 700W is currently available at FSP's online store, Shop FSP.